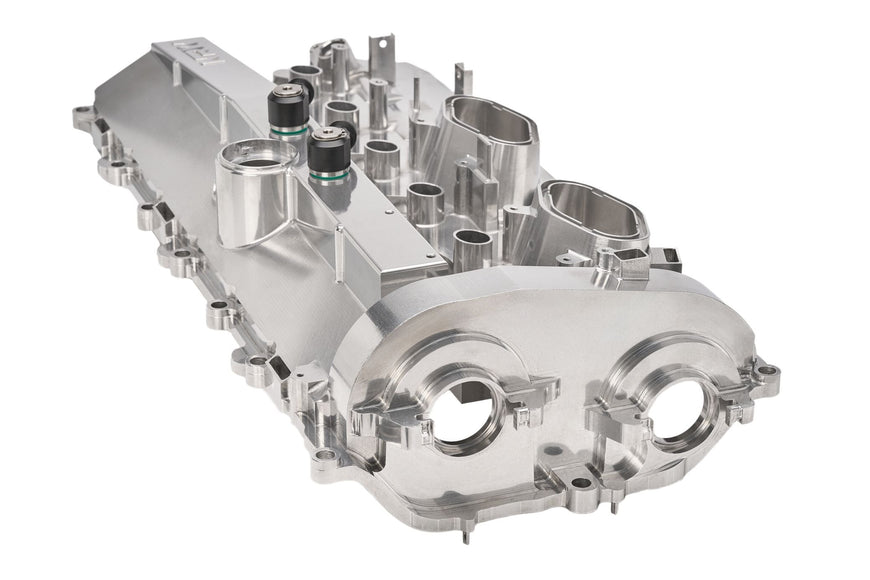

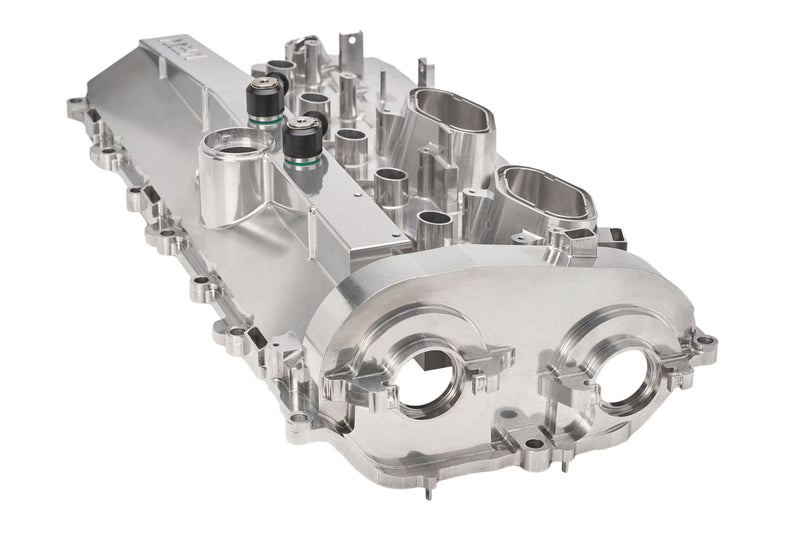

NRW Design Aluminum S65 Valve Covers

Problem Statement: The factory S65 valve covers are made from a Magnesium Alloy. While very light, Mg is known to become microporous. Over time gasses leak though the Mg material and form “pimples” on the valve cover surface. As it worsens, these pimples start to corrode the material underneath the factory coating. This continued cycle over time accelerates the oxidation of the covers leading them to fail and leak oil through the corroded areas of the vale cover. Mainly between the gasket channels. The Mg valve cover is notorious for leaking around the edge due to oxidation and corrosion to the material having contact with air and water vapor which can not be fixed with a simple gasket replacement.

Solution: NRW Design has created the first and only true 1:1 design aluminum valve cover for the BMW S65.

Benefits of the NRW Design Valve Cover:

- Aluminum is not microporous and will not oxidize or corrode.

- Aluminum is a proven material for valve covers used by many manufactures across many different models for decades. In fact, the BMW S85 V10 valve covers are aluminum. (And do not leak)

- 1:1 design means the NRW Design valve covers is an identical copy of the original S65 valve cover. All ancillary parts like gaskets, bolts, oil cap, cam sensors, plug tubes, oil separators, and coil packs work just like the original.

- Powder coated with choice of colors and finishes

- Cheaper than the original BMW valve covers

- Lifetime warranty!

NRW Design valve covers are die casted from A383 alloy. This material was chosen by NRW as it is a far superior aluminum alloy to others, due to its properties for this application. Not all casts are the same and material choice is the big deciding factor for longevity and stability of a product. Other companies claim their cast products have seen a 10x fold return due to issues using cast. Yet their metal choice (6061) is the main reason for their issues. The buying public hears the term 6061 aerospace grade and thinks it’s the far superior metal. But 6061 is an extruded metal not recommended for all casting purposes. The downfall is when making 6061 a molten metal and cooling it to a solid, it does not allow for grain structure formation, making it less suitable for casting. Creating issues down the road such as cracks and weak metal that will fatigue much quicker.

NRW Design has been in the design process of an alternative valve cover for the S65 for some time now. Way before any of these other companies started to appear on the radar. We in fact looked at making a billet version first, coming up with several designs for these covers. There appears to be at least 3 different companies around the world that have all come up with a design for their cover and if you look closely, you will see they all have something in common. Its missing a huge design BMW included in their original design. They are missing the high-pressure hump located almost midway down the cover close to the oil separators (PCV system) When the NRW Design, active Aerospace Engineers, examined this feature, it was clear it was there for a reason. This is to help control pressures and oil blow by inside the valve cover. Simply put it’s a vacuum pump design to help with pressures around the oil separators. This is something we felt could not be tampered with as it could affect the PCV system and or the reliability of your engine and its components. These other companies are neglecting this main feature of the OEM design due to cutting cost by being able to use thinner material and less machining time. If they were to incorporate this feature back into their design, their costs could almost 2x in material and machining cost.

That being said, NRW Design went to seek a different direction to solve the downfalls of the factory valve covers. We chose the casting process for these covers as many covers in the industry are cast. Including the S85 from BMW. It’s been a method forming aluminum that goes all the way back to 1895 by a guy named William “Billy” Johnson. This method is nothing new and has been mastered time and time again. Over the past few months, we have worked on perfecting the method by working with our own CNC molds to get the correct thickness and tolerances. After the cast process, we then take it to our CNC shop where we QC and inspect for any discrepancies and imperfections. Once QC is completed, we then chalk it up in our CNC machines where we mill out the spark plug holes as well as cam sensors and others. We also go in and thread all the screw holes verifying each task. Once we complete the CNC process, we then go back though yet another QC check. Making sure its ready to head to Powdercoating. This is where we customize the covers to the wishes of our customers.

We have independently had our covers tested for integrity, metallurgy, and material composition. We did this to ensure that our product will hold up though the test of time with out an issue to the end user. Our goal was to create a cost-effective product, that did not compromise the integrity of the engine and its components, and that solved the issues such as oxidation and corrosion of the factory valve covers all while giving the customer the ability to customize their valve covers.

We feel the NRW Design valve covers have reached and exceeded our goal to manufacturing an alternative solution to the factory covers. We will back this up with a lifetime warranty on all manufacturing issues associated with our covers. We really feel strongly, we have triple checked all phases of our process. Each cover will be independently serialized and that will allow us to track quality control as well as provide assurance that our covers are genuine. Our story and journey have been documented though our social media and ask that you add us on there to keep up with any and all of our latest projects. Thank you for taking the time to read our story and hope it has educated you on our process and why we went the routes we have taken to get to here today!

Thank you,

NRW Design