NRW Design S65 Inline Fuel Filter

NRW Design set out on a mission to help solve another issue that plagues our beloved E9x M3s. Over the past few years, we have seen many posts where people have experienced hydro lock from an injector that was stuck open and washing down the corresponding cylinder. Though the reason behind

this has never been resolved it still plagues our platform and causes some concern as our cars creep up in age.

Typically, an injector that fails, fails closed. Meaning fuel is stopped at the injector and the cylinder is deprived from fuel. This would be detected as a misfire and a rough running engine. But in this situation the injector is stuck open providing a steady stream of fuel in the cylinder out of sequence, which causes cylinder wash and ultimately hydro lock. When BMW designed this car, they included an in-tank filter that was to be “lifetime” but as many of you know the term lifetime means “lifetime” of the warranty. Nothing in life lasts forever. This is the only filtration within our fuel system. Though it works quite well and most will never experience this stuck open injector, we felt we could at least place another line of defense in our fuel system to help protect the longevity of our beloved E9x M3s. By providing a 10-micron filter down stream of the in-tank fuel filter this would give an added protection of anything damaging that was not caught by the in-tank fuel filter.

NRW Design went to Aeromotive and researched a ton of their work. We feel Aeromotive is one of the leading fuel delivery filtration companies and a pioneer on this expertise. Aeromotive also releases a lot of information about their fuel systems, from picking the right filter, to hot gas situations, to pressure drop tests amongst other company’s filtration devises. They catalog their data findings and makes it all public record. Something we love and took advantage of when designing our inline filter. So, thank you Aeromotive for the footwork in this project. We have built our inline filter around their replacement drop in filter as it is industry leading and easily obtained if needing to replace one’s filter. That being said, the first thing was picking the right filter. Not any filter will do and this is where you

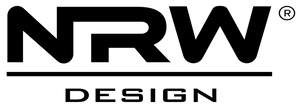

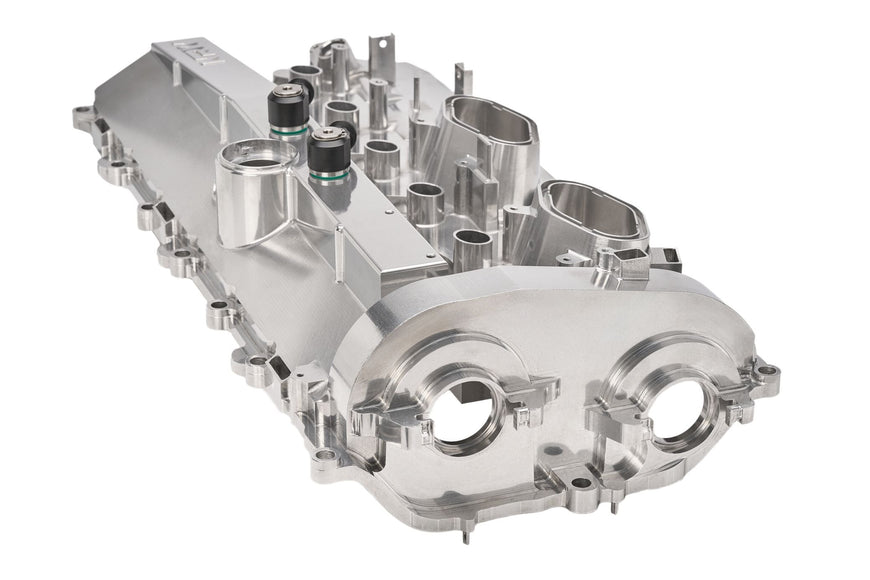

really have to watch out. The filter needs to be designed around your fuel pump, not the HP of your automobile. Picking the wrong filter can cause cavitation, starvation, and improper flow. Next is design inside the cavity and making sure the fuel is able to move freely and not finding restrictions which can lead to hot fuel situations. This also will have impact with pressure drop. Pressure drop is something you must take into consideration as you can have adequate pressure from the pump but if any restrictions along the way, you will be starving the engine from its proper fuel requirements. NRW Design set out to first design a highly efficient flowing fuel filter. If you look inside, it almost looks like a turbine engine. Very sleek, smooth walls and transitions. Its also the exact size for the filter to not

allow pressure drop as the fuel travels though the filter. NRW tested this and saw less than 1psi drop over running 90 psi fuel pressure though it. Second, we wanted to make this as if BMW built it themselves. BMW included a low-pressure fuel sensor just before the line that ties into the fuel rail meets the hard line from the pump. This sensor is important in a perfectly running S65. This sensor’s

job is to detect a drop in fuel pressure when the engine is needing it the most. The DME then tells the fuel pump to speed up by changing voltage to the pump, making the pump produce more pressure.

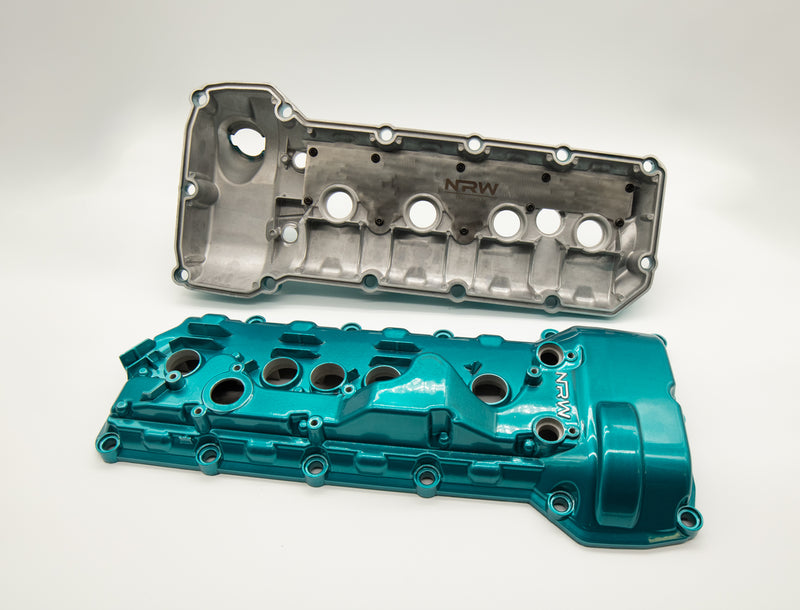

We have seen companies starting to come up with an inline filter for the s65 that negates this feature BMW intended to have in a certain place. These generic filters might provide filtration but at what expense? If the sensor is in is stock location and the filter is down stream, the car will never be able to sense this pressure drop after the filter. IE the wrong filter housing/filter for the application or simply the filter is clogging up and not able to provide adequate filtration causing a blockage and pressure and volume drop. NRW Design felt the relocation of the sensor is a must design and have included it in the filter housing itself. Of course, after the filter. Our inline filter is 100 percent made in house from 6061 billet aluminum. It’s a 2-part filter that is secured tight with a Viton O-ring. Proving a lasting seal of protection. We use Aeromotive drop in filters as they are leading standard and provide the best filtration for your application. Both Gas and E85. We have designed an aluminum bracket with rubber grommets to provide perfect fitment and vibration cancelation. Our included PTFE fuel line is perfect for both Gas and E85 applications. We are using Precision Raceworks quick disconnect fuel fittings to provide top quality pieces that make installation a breeze. We also include a low-pressure sensor block off plug with Viton O-ring as well as a screw nut that will fasten the bracket to an OEM mounting point already located in your car. In closing we feel we have hit a homerun with this inline fuel filter. This has taken us almost a year to release but we wanted to make sure it is fully tested and vetted before releasing it to the public. We have been currently running this exact setup on our cars for month now with 0 issue. Its quite nice to think for a few extra dollars of insurance we are adding an extra layer of protection to our beloved S65.

Providing the best fueling option to maintain a healthy running engine. We hope you understand our vision and this awesome project.

NRW Design